COMPARISONS BETWEEN STEAM AND OTHER TECHNOLOGIES

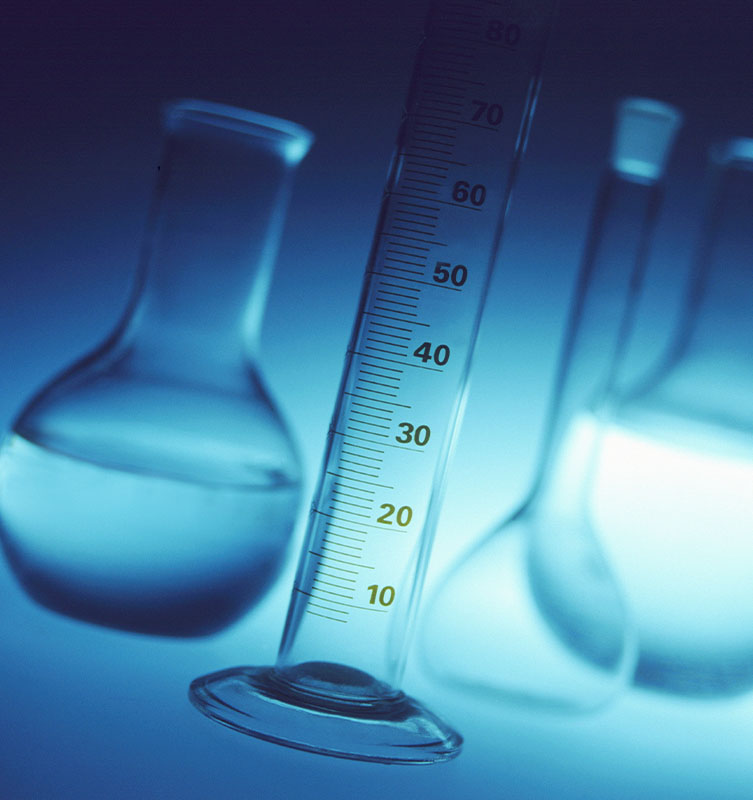

We use power generation equipment to generate Bioquell HPV Hydrogen Peroxide VaporThis is based on the formation of micro-condensations on the surfaces, which makes it more effective and also allows the biocide to reach all parts of the treated area. The physical chemistry and partial pressures of a saturated hydrogen peroxide vapor tell us that when this condensation forms the hydrogen peroxide is at a significantly higher concentration than the original 30-35% of the liquid solution. Depending on the humidity and ambient temperature, the concentration in the condensate can reach 50 or 60%, which ensures its total effectiveness and is the big difference with respect to nebulizers with a low level of disinfection.

In addition, the intelligent software monitors the main environmental factors and optimizes each cycle until the sterilization equivalent level is achieved, making them repeatable with the relevant chemical and microbiological validation.

Fogging as a method of decontamination

Fogging or atomization consists of injecting a hydrogen peroxide solution or other biocide combinations at a much lower concentration than Bioquell’s HPV-AQ peroxide which is 35%. To nebulize, the biocide is passed through a duct and mixed with air at high pressure to achieve small droplets. When the liquid comes out, it atomizes, forming a large number of micro-droplets that are dispersed by the effect of kinetic energy and are deposited on horizontal surfaces. The disadvantage of this system is that some surfaces and areas that aredifficult to access are inaccessible, so that they are not exposed to the treatment, significantly reducing its usefulness and scope.

These mist droplets typically range in size from 5 to 20 µm and average 10 µm, much larger than the vapor droplets generated by Bioquell’s equipment, which are less penetrating and therefore less effective.

Ozone Decontamination

The disadvantages of this disinfection system are as follows:

- It has a strong oxidizing character, so it can damage sensitive electronic equipment.

- Special measures must be taken to work with ozone and avoid exposure of workers as it is a toxic gas that causes irritation of mucous membranes and in some extreme cases, pulmonary edema.

- The ECHA (European Chemicals Agency) classification inventory reports the classification of this substance as hazardous by air, skin irritation and eye damage.

- The disinfected space should be adequately ventilated before reuse by the general public.

- Due to its tendency to decompose and generate oxygen, it is extremely reactive.

- Its efficacy against Co-VID-19 has not been demonstrated.

- It is not authorized for use as a biocide in a hospital environment.

Information Note on the Use of Biocidal Products against Co-VID-19

UV light decontamination

Decontamination with ultraviolet light, unlike the other methods mentioned, is a physical and not a chemical method. When bacteria, viruses and protozoa are exposed to the germicidal wavelengths of UV light, they become unable to reproduce and infect.

Its efficacy is related to the distance between the light source and the surface to be treated, so that maximum biocidal effects only occur at relatively short distances. Depending on exposure times and distances, it can achieve a log 4 reduction (99.99%) of Clostridium difficile and a log 5 reduction (99.999%) of other less resistant microorganisms (MRSA, VRE, CRE), far from the reduction achieved by Bioquell (log 6 or 99.9999%).

Its great disadvantage is the shaded areas, where the biocidal effect is null. For the same room, it is necessary to make several cycles in different positions to reach all the shaded areas.

Only hydrogen peroxide vapor reaches all corners and hard-to-reach surfaces in a single treatment, with efficacy equivalent to sterilization and, most importantly, fully validatable by both chemical and biological indicators.